Overview of Demo Projects Around the World for Floating Offshore Wind Turbines

Overview of Demo Projects Around the World for Floating Offshore Wind Turbines

By 2023, many floating wind energy concepts have successfully completed the prototype demo stage. A successful demo project is essential for the eventual commercial implementation of a wind farm. New floater designs, such as TaidaFloat and DeltaFloat, developed in Taiwan require a demo project to support their development. This technical article provides an overview and analysis of successful demo projects worldwide and ideas for planning a demo project in Taiwan. The article provides insight into how a demonstration project can be carried out in Taiwan Strait or other locations and its possible cost.

Overview of Recent FOWT Demo Projects

Land-based wind turbines have been around since James Blyth generated electricity with them in 1887. They become popular and are widely installed for power generation since the 1990s.

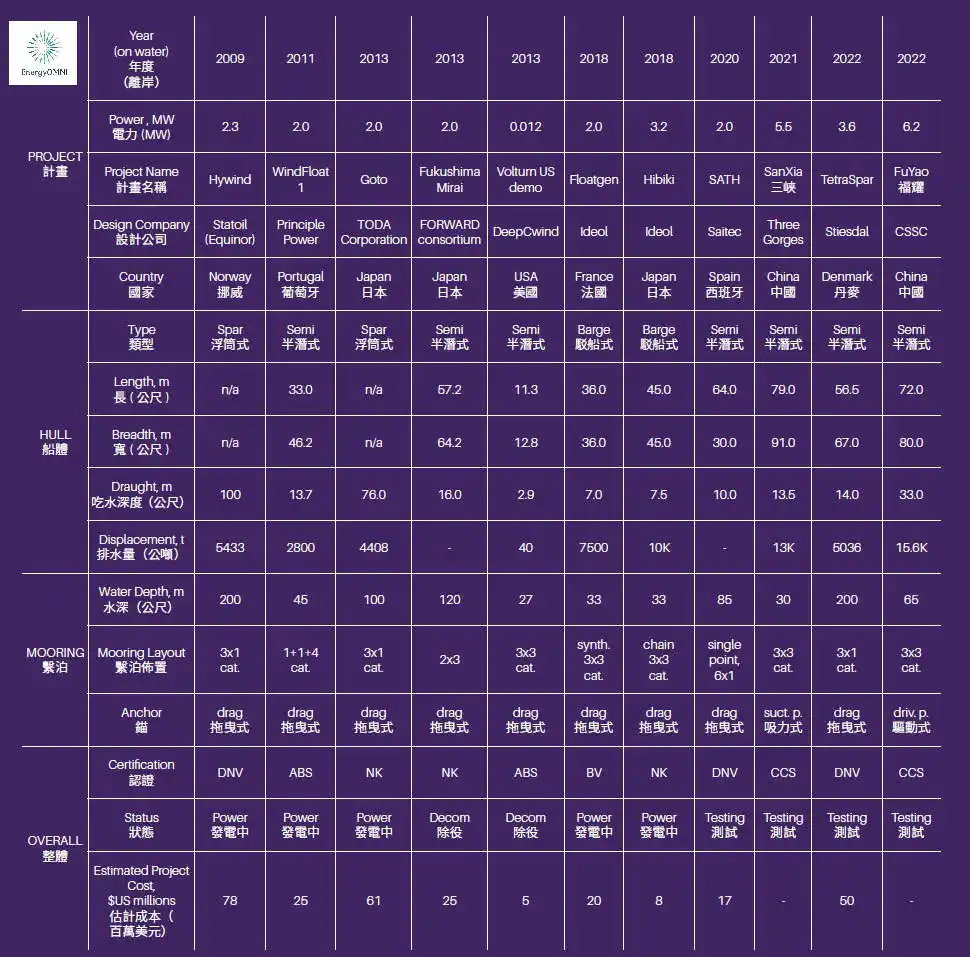

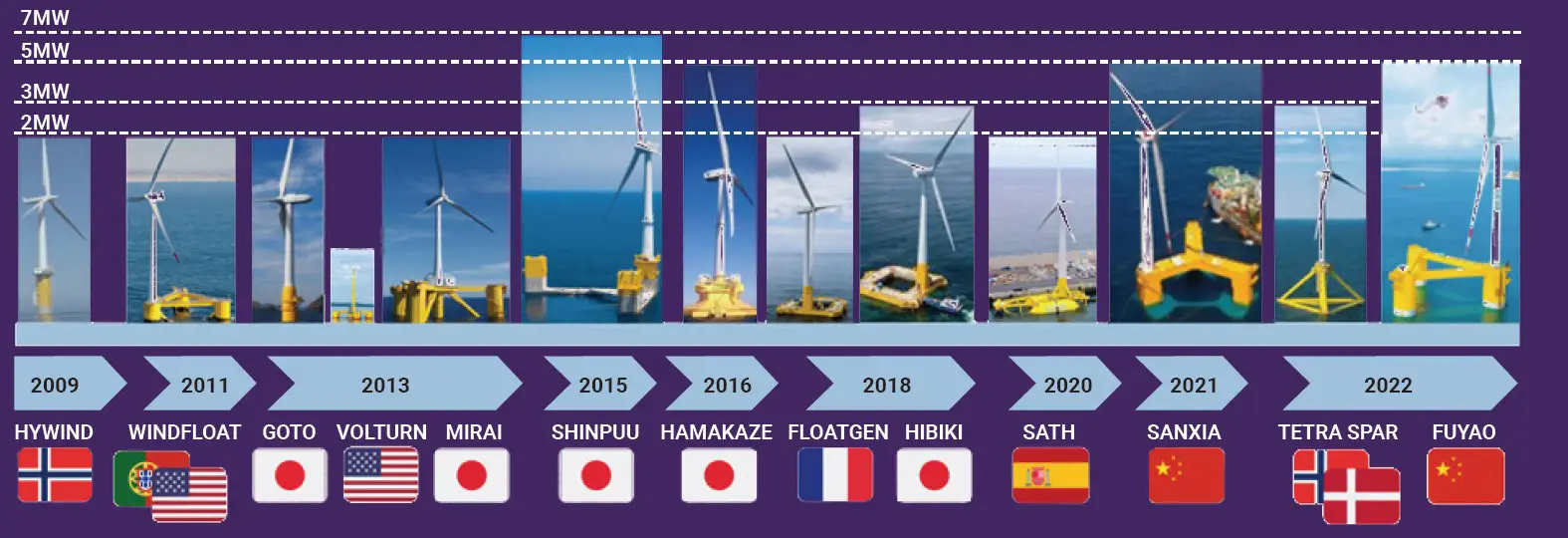

In 2009, the first Floating Offshore Wind Turbine (FOWT) demo was installed by Statoil (now Equinor). Since then, there were extensive trials and demo projects in the few countries taking part, sometimes predating the actual farm construction by a decade. A lot was learned from the demonstration project, and the designs were adjusted. Table 1 shows all public demonstrator projects launched on the water before September 2022 in chronological order.

Hywind and Tetraspar in Scandinavia

It is a breakthrough that Norway, a leader in renewable energy, pioneered the earliest FOWT demo project as far back as 2009. It provided confidence that FOWT can work (Reference 1) and empowered Norway to become the leader in FOWT too. It is still worth noting, that many years have passed between this demo and the full-scale Hywind spars - showing that much work in every direction had to be done to make the full-scale farm viable. For most projects financing was difficult - but maybe not for Hywind, since it was founded by Statoil – an oil and gas company, as part of its efforts to pursue clean energy. The demo is a test facility and will be providing power until 2029. It led to the current implementation of the world’s largest floating wind farm, Hywind Tampen. The project has 11 spars in the wind farm which supplies electricity to oil and gas platforms.

Another Scandinavian project is shown in Figure 1 – TetraSpar (Reference 2). The most recent demonstrator launched in 2022. With a turbine of 3.6 MW, strictly speaking, it's not a demo, but a full-scale platform. It is designed to be small and mass-produced. Developing his latest floating design had cost around $50 million, a sum financed by a trio of leading energy companies. The designer, the famous Henrik Stiesdal, was hoping to convince them that the platform design would stand out in a crowded group of competitors. Interestingly, after the demo launch, a pure semi-sub was presented for future use instead; TetraSub (Reference 3) might indicate the novelty and evolving aspects of the TetraSpar concept.

The majority of European fixed offshore wind turbines were erected in the relative safety of the calm Baltic Sea, enabling comfortable installation operations and low extreme loads. With Norway and the UK becoming the leaders in the floating wind, the focus has shifted to the North Sea, with mean wave heights as high as 11 meters (Reference 4) and more frequent storms. This presented new challenges to structures' survivability but also provided better-quality wind areas. As with the global economy, the focus is shifting to Asia now, with Japan being the first country to complete a large-scale FOWT back in 2015, and Taiwan, in particular, investing heavily in the wind industry. Unfortunately, Asian developments have to face a local weather phenomenon, typhoons. In addition to the constant monsoons in autumn and winter, typhoons occasionally ravage East and South Asia during summer and autumn. Because of the forces induced by typhoons, the wind turbine and the platform must be designed accordingly.

Figure 1 Timeline of FOWT demo projects around the world

WindFloat in Portugal/USA and VolturnUS

Perhaps the most important demonstrator project is WindFloat, (Reference 5) as it had become the role model and precursor to commercial FOWT. During 3 years of demo operation offshore Portugal, the USA-designed prototype encountered record storms several times more than expected. It has successfully withstood record 17 m waves, which was much higher than the design wave. That also shows how important it is to not only consider the predominant waves but also the extremes. After its operational life of 5 years has expired, (Reference 6), it was nevertheless sold and placed at Kincardine, Scotland. The demo led to the successful implementation of two small pre-commercial wind farms, WindFloat Atlantic with 3 semis offshore Portugal and WindFloat Kincardine with 5 semis offshore Scotland. According to Principle Power in USA, (Reference 7) they raised $25M for the design, fabrication, and installation of the prototype off the coast of Portugal. Funding for the project came from the Portuguese government and from a joint venture, called WindPlus that included Energias du Portugal, Repsol (Spanish oil company), A. Silva Matos (Portuguese manufacturer), Vestas, and government innovation funds.

Unlike most commercial projects, the data from the Volturn US demo (Reference 8) was published in full detail, moreover used for the verification of simulation softwares’ predictions: it proved simulations to produce believable results. (Reference 9) It has also explored the towing operations in detail. However, the turbine used was extremely small and despite the success, it didn’t immediately ignite full-scale FOWT development in the US, and even 10 years later there are no active projects. Decommissioned after 18 months and disassembled.

Mirai, Shinpuu, and Goto in Japan

Fukushima Mirai (Reference 10) with a 2MW turbine was a successful project among the four (4) Fukushima Forward platforms. (Reference 11) Many made-to-measure technologies were developed for it by different Japanese institutions, even custom mooring chains with custom steel grades. Among other projects, Fukushima Forward has seen the largest number of different institutions pooling their money ($115 million for the whole Forward project) and efforts together to make it the largest scale and longest demo project. Decommissioned in 2021. It is interesting to note that the scientist behind the project from the start is the consortium's technical advisor, Professor Ishihara Takeshi of the University of Tokyo, who recalled: "The most difficult thing was persuading companies to take part… Over and over, we had to beg companies that said initially that they couldn’t participate. And the government had to really struggle to raise the money." (Reference 12) Not all projects were so smooth, but valuable lessons can be learned when things deviate from the plan. Data from Fukushima Hamakaze, with a 5 MW turbine, was used to validate software predictions, (Reference 13) the simulation didn't save it from gaining a 45-degree tilt during towing in 2016 due to problems with ballasting; this led to the disassembly of the platform. (Reference 14) Shimpuu with a 7 MW turbine was an innovative concept in many ways. It is an L-shaped semi-submersible with three square-section columns, but only two pontoons. It has the largest displacement among FOWT at the time. It was salvaged due to the project being considered unprofitable. Total decommissioning works for Mirai, Hamakaze and their offshore power substation were tendered for $48 mil. (Reference 15) The lesson learned is that the decommissioning cost can be quite high, and it should be included in the initial cost assessment.

Also in Japan, a spar-type platform Goto Demo (Reference 16) has successfully withstood two severe typhoons without loss of stability, and no structural damage or cracks were found upon later physical inspection. Goto Demo was very similar to Hywind, not just because it's a spar, but because after staying afloat for 3 years of operation that finished in 2016, engineers behind it (similar to Fukushima, from many partnered institutions) took a pause to reflect on the lessons learned. To utilize the full-scale model for further demonstration toward commercialization, it was removed from the site and relocated to 5 km offshore of Fukue Island. There, a full 2-MW power generation is possible, and future expansion to a floating offshore wind farm is expected. Now the construction of the 16.8 MW Goto floating wind farm offshore Japan is scheduled to start in September, and the wind farm is expected to be commissioned in January 2024 (Reference 17)。

On another note, Skwid (Reference 18) was the first vertical wind turbine to be tested in Japan, but in 2014 it sank during the installation process 1.2 km off the coast of Kabe Island. The communicated reason was improper anchoring, reminding of the necessity of proper sea bottom investigation and the installation procedure, as well as of necessity of thoughtful design of even such a routine procedure as anchoring. The platform was salvaged in the end. (Reference 19)

Totally, Japan had 5 different large-scale actually built prototypes, which puts it in the first place in this metric. This was achieved by two factors: first was close academia-industry integration, when dozens of companies and universities partnered in consortiums, which handled their specific FOWT project. The Japanese universities provided creativity and novelty to their experienced and resourceful industrial partners. There is also a similar consortium in the US: DeepCWind, in charge of the VolturnUS project. However, the full-scale version of the platform wasn’t built yet despite a decade of preparation. Japan’s faster pace in this race can be attributed to the second factor: government political support and funding. Japan's government planned to use the Fukushima Project as a reconstruction effort for the province affected by the Fukushima Nuclear Disaster. (Reference 19) This project was only one of several planned to meet the green energy transition goals. However, in the US, despite advances in science and technology, Green Energy was not in the political focus at the time, project funding was limited, and permission processes are too long and difficult to attract private companies. It ultimately resulted in Principle Power, a private company headquartered in California, USA, testing and then successfully installing its platforms in Portugal and the UK, in cooperation with several European agencies, instead of developing it in the US.

FuYao and SanXia in China

With a large design displacement of 15,600 tons, it may be difficult to call FuYao (Reference 20) FOWT a "demo", however, this 6.2 MW platform is planned to serve as a technology demonstration before the even bigger turbines are built for commercial use in China. As is often the case with many Chinese projects in any industry, the scale is unparalleled, despite FuYao being a rather conventional configuration (3 columns, off-centre turbine, boasting both pontoon and bracing). Another design that challenges conventionality is also afloat: SanXia.(Reference 21) Both of them are deployed in the South China Sea, but not much technical information or papers could be found, and structural as well as financial details could not be found publicly.

Floatgen in France

A French company Ideol strongly believes in concrete as the construction material because it is cheaper, but the Japanese think otherwise. (Reference 22) So, in 2018, they simultaneously launched two sister demonstration projects – concrete Floatgen (Reference 23) in France and steel Hibiki (Reference 24) in Japan, curiously, a steel barge in Japan seems to still cost less to build than a concrete barge in France. It's interesting to see, how one design can be adapted to very different details: 3 vs 2 blade turbine, synthetic vs chain mooring, concrete vs steel hull, BV vs ClassNK class. Although said to have already faced three typhoons since its commissioning, barge-type platforms were shown to be susceptible to huge turbine loads in case of pitch motion resonance with incident waves. (Reference 25) It’s curious to see whether these concerns have been addressed by Hibiki's engineers, and how the fatigue damage might potentially manifest itself after many years.

In France, it is supported by the European Union as part of the FP7 program, by the French Environment and Energy Management Agency as part of the national Investments for the Future Program, and by the regional government. After the projects had been finished, it was decided to let them keep producing energy for longer, and Ideol signed an investment agreement with a few companies aiming at financing innovative infrastructure projects funded by the Investment for the Future Program. To their technical merits, in 2023, Floatgen reported achieving a 60% capacity factor throughout the year, (Reference 26) promising much better real efficiency than the usually planned 40%. It is worth noting the fundraising stage took many years to persuade investors; BW Ideol's press releases described the process and sums of money in its detailed press release. (Reference 27)

Trend of Demo Projects

Of these demo projects, their principle dimensions, turbine ratings, cost and other data are compiled and listed in Table 1. Data sources include press releases, scientific publications and news articles. The grey colour in the table signifies concrete structure. The readers are referred to another conference paper by the same authors in 2021 for a similar comparison of full-scale semi-sub FOWT projects. (Reference 28) From Table 1, a few observations about the current state of FOWT demonstrators can be made.

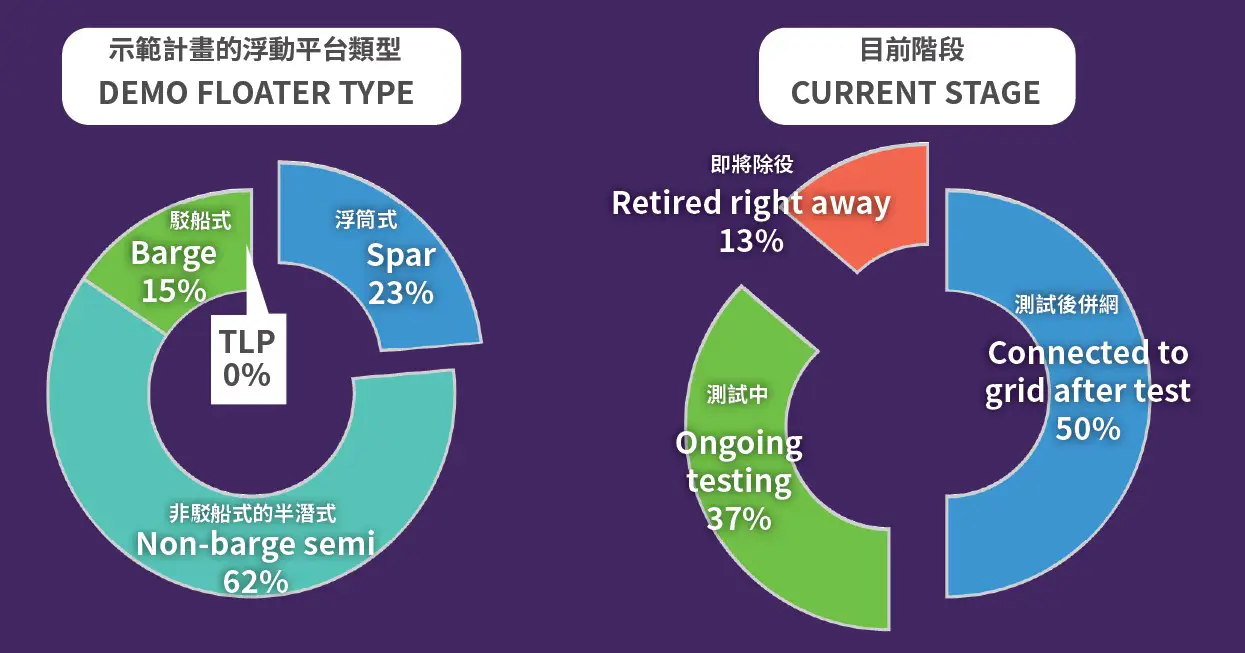

Semi-submersible type floaters are in the absolute majority, 8 out of 13 belonging to this category, while 2 of these 13 are barge type. The remaining 3 are spar type, and no TLP demonstrators have been launched so far, except for a tiny 80 kW prototype done in Italy. (Reference 29) Spar-type FOWT don’t vary much from one another, and as a direct successor of fixed-bottom columns, they are easier to design, therefore the development of this FOWT type has already moved to industrial scale and away from demo projects, while semi-submersibles concepts vary greatly and therefore new innovational concepts are being actively tested and demonstrated. The widely discussed TLP technology seems not to be field-ready yet, or no interested parties are funding it.

Funding is a crucial part of demo projects. Among the successfully completed projects, only a small part was retired, while most projects are connected to the grid after test and continue to produce power – this is a key point for investors, as demo projects deemed unprofitable had been canceled. These trends are visualized in Figure 2.

Figure 2 Floater type and current stage of FOWT demo projects

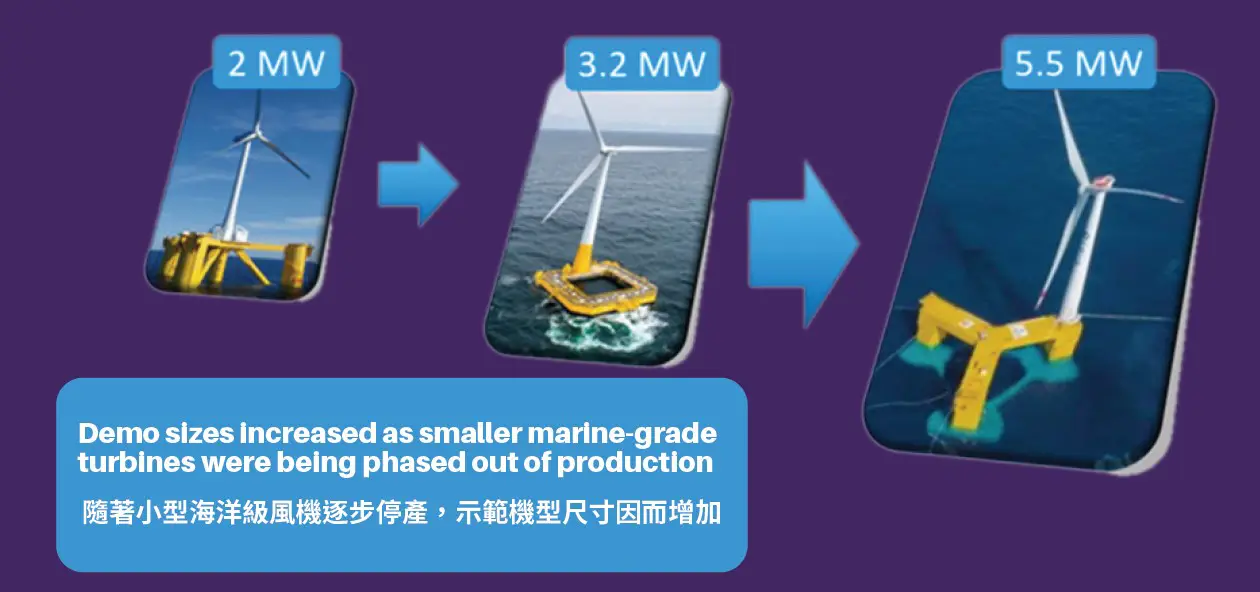

An increase in floater displacement and power rating can be seen as new demonstrators have to keep up with smaller turbines being phased out of production. While 2 MW turbines were the standard for early projects, fixed and floating offshore wind turbines were growing in size, (Reference 30) as shown in Figure 3 Turbine manufacturers reacted to the demand and produce larger turbines, phasing out the smaller ones. An offshore 2 MW turbine can only be custom-made in 2022 and no longer mass-produced, forcing demonstration projects to adopt higher power ratings. Another factor here is the expectation from investors not only to gain technical data but also get sell the electricity provided by the demo, while in the early projects revenues from electricity were rarely considered.

As the platform's dimensions are governed mainly by stability and seakeeping requirements, and not by turbine weight, a big increase in turbine power will only lead to a small enlargement of a floater. Bigger turbines are only available for offshore projects, as a hundred meters long the blades and nacelles could not pass through most roads, tunnels and bridges. Fueled by the desire for efficiency, even offshore turbines have grown so large that they can't be handled by most port cranes, and almost no factories can produce nacelle bearings of diameters about 10 meters, that’s why in 2023 Vestas CEO halted many people's dreams of 30 and 50 MW turbines, saying the 15 MW turbines are big enough for now and will not grow soon. (Reference 31)

Figure 3 Trend of FOWT demo size

Figure 3 Trend of FOWT demo size

For the subsea parts (i.e. mooring components), all demos have been exclusively using drag anchors before both Chinese projects' experiments with suction and driven piles. It is reasonable as drag anchors are the cheapest choice, but there are many potential benefits accessible to other anchor types, such as anchor sharing, precise anchoring location, fast and easy installation with small vessels, etc. Mooring layout is usually a 3x3 catenary chain, while some designs opt for 3x2 or even 3x1 using large-diameter chains. Using fewer chains, but bigger chains helps reduce installation time, saving vessel hiring costs, which is one of the major concerns in the whole industry. However, 3x1 or single point moorings provide no redundancy in one-line damaged condition, and thus no reliability in case of a mooring failure.

Developments for Taiwan

In Taiwan, wind energy has been a development focus, since the political decision to phase out nuclear power plants, as other sources of renewable energy are hardly accessible here. (Reference 32) Floating wind research has also started to gain traction. Recently, a wave tank test of a barge-type FOWT was conducted. (Reference 33) The authors also participated in an indigenous design of DeltaFloat semi-submersible. Another notable design in Taiwan may arguably be the TaidaFloat semi-submersible, (Reference 28) which was designed by a team including both authors. The team from National Taiwan University was sponsored by Taiwan's government agency, the Ministry of Science and Technology, to come up with a reference platform, best suitable for Taiwan’s local environment and manufacturing conditions, and possibly to serve as a workable design for wind energy developers. A smaller version of TaidaFloat and DeltaFloat is currently being designed as a prototype for technology readiness demonstration.

The amount of financing required for such a project is hotly debated. According to Table 1, the average FOWT demo project cost (excluding VolturnUS mini project) amounts to $35.5 mil (NTD 1084 mil), and the projects get cheaper with time due to the learning curve. Please keep in mind that this figure is for reference only, as the costs shown in Table 1 compare different projects based on limited data available in the media.

Conclusions and Learnings

After analyzing previous demo projects, several key points were learned for designing a new prototype demonstrator:

First, funding is the essence of a successful demo program. The Japanese government is willing to spend an enormous amount of money on FOWT projects. European projects are usually private-government partnerships, while the US only most recently decided to develop floating wind at all 34. Recently, the UK decided to invest 31.6 million pounds into FOWT demo projects 35. The progress of different countries in FOWT technology is clearly seen from the above analysis, so for a new country, such as Taiwan, to enter the industry and catch up with the current players, a clear policy must be outlined by the government, with regulations facilitating wind sites lease, governmental funding of both research and demo projects, as well as a free energy market to encourage private investment in the sector. A key to a successful and swift demo project erection is amassing a large number of interested stakeholders. A good point to make with them is that the demo FOWT keeps producing energy and is not thrown away after a couple of years. Most of the initially decommissioned platforms were repurposed to keep power production going for years.

Second, construction and development costs vary greatly by country, for example, a steel barge in Japan costs less than a concrete one in France, where concrete was used intentionally to cut costs. Every country or region deciding to commence its FOWT project should develop a design fitting its own industrial situation, and not necessarily buy a foreign design. The demo floater dimensions, materials, and other design choices should originate from the local industry compatibilities and infrastructure.

Third, interesting enough, every project mentioned had some degree of academic collaboration. Student researchers and professors from the University of Tokyo, Massachusetts Institute of Technology, Danish Technical University, Centrale Nantes, and many other renowned and smaller institutions were directly involved in the design of the floaters, with master's and Ph.D. theses defended as a result. As FOWT is a very new and unexplored technology domain, only with the help of researchers, companies can ensure their design will be advanced, safe, and reliable.

Reference:

1. Skaare, B., et al., Analysis of measurements and simulations from the Hywind Demo floating wind turbine. Wind Energy, 2015. 18(6): p. 1105-1122.

Available from: https://onlinelibrary.wiley.com/doi/pdfdirect/10.1002/we.1750?download=true.

2. Borg, M., et al., Technical Definition of the TetraSpar Demonstrator Floating Wind Turbine Foundation. Energies, 2020. 13(18).

Available from: https://mdpi-res.com/d_attachment/energies/energies-13-04911/article_deploy/energies-13-04911-v2.pdf?version=1600767522.

3. Tetra offshore foundations for any water depth | Stiesdal. 2022; Available from:

適用於任何水深的 Tetra 離岸基地| Stiesdal。 2022。

Available from: https://www.stiesdal.com/offshore/tetra-offshore-foundations-for-any-water-depth/.

4. Wahle, K., et al., An atmosphere–wave regional coupled model: improving predictions of wave heights and surface winds in the southern North Sea. Ocean Science, 2017. 13(2): p. 289-301.

Available from: https://dx.doi.org/10.5194/os-13-289-2017, https://os.copernicus.org/articles/13/289/2017/os-13-289-2017.pdf.

5. Roddier, D., et al., WindFloat: A floating foundation for offshore wind turbines. Journal of renewable and sustainable energy, 2010. 2(3): p. 033104.

6. Roddier, D., et al. Summary and Conclusions of the Full Life-Cycle of the WindFloat FOWT Prototype Project. in ASME 2017 36th International Conference on Ocean, Offshore and Arctic Engineering. 2017.

Available from: https://doi.org/10.1115/OMAE2017-62561, https://asmedigitalcollection.asme.org/OMAE/proceedings-abstract/OMAE2017/57779/V009T12A048/279362.

7. Power., P., Principle Power WindFloat Pacific Pilot Project, U.S.D.o.t.I.B.o.O.E. Management, Editor. 2013, Bureau of Ocean Energy Management: USA.

Available from: https://www.boem.gov/sites/default/files/renewable-energy-program/State-Activities/OR/WindFloat-Pacific-Lease-Request.pdf.

8. Dagher, H., et al., The VolturnUS 1:8 Floating Wind Turbine: Design, Construction, Deployment, Testing, Retrieval, and Inspection of the First Grid-Connected Offshore Wind Turbine in the US. 2017: United States. p. Medium: ED; Size: 61 p.

Available from: https://www.osti.gov/biblio/1375022, https://www.osti.gov/servlets/purl/1375022.

9. Viselli, A.M., et al., Design and model confirmation of the intermediate scale VolturnUS floating wind turbine subjected to its extreme design conditions offshore Maine. Wind Energy, 2016. 19(6): p. 1161-1177.

10. Yamaguchi, H. and A. Imakita. Learning from field test regarding damping of a floater motion-2mw fowt “Fukushima Mirai”. in Grand Renewable Energy proceedings Japan council for Renewable Energy (2018). 2018. Japan Council for Renewable Energy.

11. Kinoshita, S. Failure of world's 1st offshore floating wind farm in Fukushima disappoints 3.11 survivors - The Mainichi. 2022.

12. Takaaki, N. Offshore Wind Power Promises to Boost Fukushima Recovery. 2014.

13. Yoshimoto, H., et al., Validating numerical predictions of floating offshore wind turbine structural frequencies in bladed using measured data from Fukushima Hamakaze. Proceedings of the EERA Deep Wind, 2019.

14. OffshoreWind. Fukushima Hamakaze Spar Tilts Back Into Position. 2016; Available from:

Available from: https://www.offshorewind.biz/2016/05/17/fukushima-hamakaze-spar-tilts-back-into-position/.

15. International, O., Japan to decommission floating offshore wind test turbines, in Ocean Energy Resources International. 2020.

Available from: https://ocean-energyresources.com/2020/12/20/japan-to-decommission-floating-offshore-wind-test-turbines/.

16. Utsunomiya, T., et al. Floating offshore wind turbine demonstration project at Goto Islands, Japan. in OCEANS 2014-TAIPEI. 2014. IEEE.

17. Durakovic, A. Japan's First Floating Offshore Wind Farm Nears Construction Phase. 2022.

18. Mohan Kumar, P., et al., Review on the Evolution of Darrieus Vertical Axis Wind Turbine: Large Wind Turbines. Clean Technologies, 2019. 1(1): p. 205-223.

Available from: https://www.mdpi.com/2571-8797/1/1/14.

19. Weston, D., Japanese hybrid floating turbine sinks, in WindPower Monthly. 2014.

Available from: https://www.windpowermonthly.com/article/1327126?utm_source=website&utm_medium=social.

20. Ccs China's first deep-sea floating wind power platform "Fu Yao" was successfully connected. 2022.

21. Xiaoyu, L. "SanXia YinLing Hao" Chinese FOWT, I am "Wall breaker". 2022.

22. Choisnet, T., B. Geschier, and G. Vetrano. Initial comparison of concrete and steel hulls in the case of Ideol’s square ring floating substructure. in Proceedings of the 15th World Wind Energy Conference and Exhibition, Tokyo, Japan. 2016.

23. Choisnet, T., et al., Performance and mooring qualification in Floatgen: the first French offshore wind turbine project. 16ième Journées de l’Hydrodynamique, 2018. 1: p. 1-10.

24. BW, I. Hibiki. 2022;

Available from: https://www.bw-ideol.com/en/japanese-demonstrator.

25. Jonkman, J.M., Dynamics modeling and loads analysis of an offshore floating wind turbine. 2007: University of Colorado at Boulder.

26. Ideol, B. Floatgen achieves a continuous capacity factor of nearly 60%. 2023;

Available from: https://www.bw-ideol.com/en/floatgen-achieves-continuous-capacity-factor-nearly-60.

27. Paul, d.l.G., Ideol Press Kit. 2023, BW Ideol.

Available from: https://www.bw-ideol.com/sites/default/files/2019-10/Ideol%20-%20Press%20kit_0.pdf.

28. Hsu, I.-J., et al. Optimization of Semi-Submersible Hull Design for Floating Offshore Wind Turbines. in International Conference on Offshore Mechanics and Arctic Engineering. 2022. American Society of Mechanical Engineers.

29. Chen, J. and M.-H. Kim, Review of Recent Offshore Wind Turbine Research and Optimization Methodologies in Their Design. Journal of Marine Science and Engineering, 2022. 10(1): p. 28.

Available from: https://www.mdpi.com/2077-1312/10/1/28.

30. ClimateWire Offshore Wind Turbines Keep Growing in Size. 2022.

31. Bloomberg, Vestas CEO: Wind turbines are big enough for now, in TheStar. 2023.

Available from: https://www.thestar.com.my/business/business-news/2023/01/18/vestas-ceo-wind-turbines-are-big-enough-for-now.

32. Hung-Chun, C., et al., Prospects of offshore wind power in Taiwan and the development of semi-submersible floating platforms, in Taiwan Wind Energy Association Conference. 2022, Taiwan Wind Energy Association: Tainan, Taiwan.

33. Yang, R.-Y., et al., The 1: 20 scaled hydraulic model test and field experiment of barge-type floating offshore wind turbine system. Ocean Engineering, 2022. 247: p. 110486.

34. House, T.W. FACT SHEET: Biden-Harris Administration Announces New Actions to Expand U.S. Offshore Wind Energy | The White House. 2022 2022-09-15;

Available from: https://www.whitehouse.gov/briefing-room/statements-releases/2022/09/15/fact-sheet-biden-harris-administration-announces-new-actions-to-expand-u-s-offshore-wind-energy/.

35. Buljan, A. UK Pours GBP 31.6 Million Into Floating Wind Demo Projects. 2022.

Glib Ivanov

A Ph.D. student at National Taiwan University, originally from Ukraine, is pursuing his doctoral degree. His research centers around the structural design of a semi-submersible platform called TaidaFloat. Alongside his academic pursuits, he also enjoys converting scientific data into fun arts.

Kai-Tung Ma

Born in Taipei, Professor Kai-Tung Ma holds a Ph.D. from U.C. Berkeley and teaches at National Taiwan University currently. Recognized as a Yushan fellow by the Ministry of Education and a fellow of the Society of Naval Architects and Marine Engineers in the U.S., Professor Ma brings a wealth of expertise to his field. With previous experience in the oil and gas industry, providing engineering support for offshore projects, Kai-Tung Ma has also authored textbooks and published numerous academic papers.

More related articles